Copyright © 2023 by "PDJ " · All Rights reserved · https://www.PDJinc.com

Routers and Mills

Pilot Pro CNC

5 Prime CNC

Get a Quote

CNC Parts

CNC Plans

Testimonials

CNC FAQs

Contact Info

Pilot Pro CNC

5 Prime CNC

Get a Quote

CNC Parts

CNC Plans

Testimonials

CNC FAQs

Contact Info

-Your New "Robo-Shop"-

We Pioneered Multi-Purpose CNCs Back in 1998 -

And still going STRONG!

Multi-Axis Router Milling Laser Extruder Plasma Hot-Wire Knife Camera ETC!

CNC - FAQ & Tips

Sales Questions - sales@pdjinc.com

Technical Questions - pdj@pdjinc.com

FAQ

Specfication sheet - Click this.

----------------

All this Quality at such a low price – HOW? Our goal has always been “Help those that want

to create”. Our mission is to build a family of makers and grow with them.

----------------

Payment options - The best method is a Bank Transfer, we also except Paypal (+ 2.9%

paypal fee) and their LOAN service "Bill Me Later", or snail mail business or cashier’s

check. Email us for your quote, an invoice, or more information.

----------------

Our lead time goal is 4 weeks, 4 to 6 weeks depending on our current work load. Late deliveries to us can increase this time. meantime we get you started on the software side.

----------------

Technical Questions - pdj@pdjinc.com

FAQ

Specfication sheet - Click this.

----------------

All this Quality at such a low price – HOW? Our goal has always been “Help those that want

to create”. Our mission is to build a family of makers and grow with them.

----------------

Payment options - The best method is a Bank Transfer, we also except Paypal (+ 2.9%

paypal fee) and their LOAN service "Bill Me Later", or snail mail business or cashier’s

check. Email us for your quote, an invoice, or more information.

----------------

Our lead time goal is 4 weeks, 4 to 6 weeks depending on our current work load. Late deliveries to us can increase this time. meantime we get you started on the software side.

----------------

TIPS

Your First 5 axis project - download the code here - Click This.

----------------

Your First 3 axis project - download the code here - Click This.

----------------

Tutorials on some things you can do from Vectric - Click This.

----------------

Setting up the VFD - Click this

---------------

Cutting aluminum - Use the right cutter, 2 flute helix. Use spiral entry for Z axis.

----------------

The control box should be the last turned on and the first turned off. First power up the PC, then start mach3, now the control box. Reverse to turn off.

----------------

Never remove the ball nut from the lead screw or the ball bearing will fall out, email for instructions.

----------------

Do I use grease? No, use only 30w oil on the rails and lead screws. The ball nuts need grease fittings to plug the hole but just add an inch or so of oil forward and aft with an oil can on all linear moving parts.

----------------

What do I do with hardware without a locking mechanism? Use medium thread lock on all hardware that does not use a lock washer or lock nut. Do not lock things down until everything is tested.

----------------

Your First 5 axis project - download the code here - Click This.

----------------

Your First 3 axis project - download the code here - Click This.

----------------

Tutorials on some things you can do from Vectric - Click This.

----------------

Setting up the VFD - Click this

---------------

Cutting aluminum - Use the right cutter, 2 flute helix. Use spiral entry for Z axis.

----------------

The control box should be the last turned on and the first turned off. First power up the PC, then start mach3, now the control box. Reverse to turn off.

----------------

Never remove the ball nut from the lead screw or the ball bearing will fall out, email for instructions.

----------------

Do I use grease? No, use only 30w oil on the rails and lead screws. The ball nuts need grease fittings to plug the hole but just add an inch or so of oil forward and aft with an oil can on all linear moving parts.

----------------

What do I do with hardware without a locking mechanism? Use medium thread lock on all hardware that does not use a lock washer or lock nut. Do not lock things down until everything is tested.

----------------

3 to 6 Axis - Any Configuration

1) 3 axis typical X, Y, Z arrangement

2) 4th axis on the table (pancake style), 5th axis on the Z

3) 4th axis on the table (lathe style), 5th axis on the Z

4) 4th and 5th axis on the Z (BC drive)

5) Add a rotary axis to the table with #4 and it is a 6 axis machine.

2) 4th axis on the table (pancake style), 5th axis on the Z

3) 4th axis on the table (lathe style), 5th axis on the Z

4) 4th and 5th axis on the Z (BC drive)

5) Add a rotary axis to the table with #4 and it is a 6 axis machine.

We offer 2 CNC designs;

The differences between the Pilot Pro CNC and the 5 Prime CNC is -

Pilot Pro CNC - 5" Z axis and 12" Z axis

5 Prime CNC - 20" Z axis

----------------

The 4th axis - 12" Z axis is recommended for 4th axis operation. The Pilot Pro with 12" Z

option or the 5 Prime is requiered.

The BC drive (2 DOF) - The 4th and 5th axis mounted on the Z axis. 5 Prime CNC with 20"

Z axis travel is recommended.

----------------

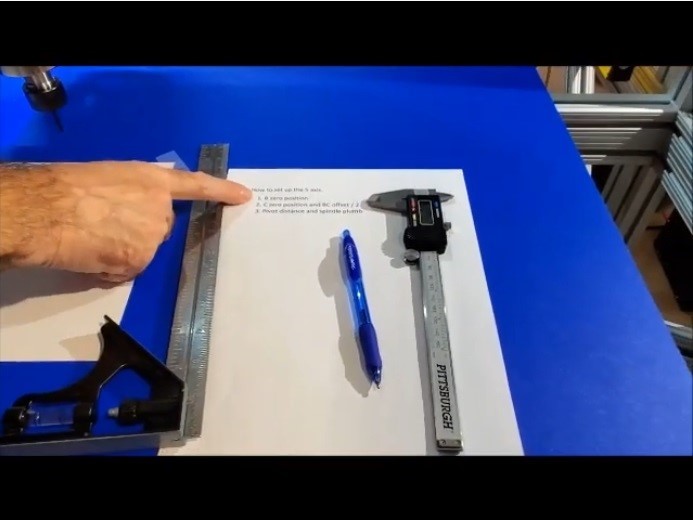

Setting up the BC drive is easy to do - Here is a video on how to do it

The differences between the Pilot Pro CNC and the 5 Prime CNC is -

Pilot Pro CNC - 5" Z axis and 12" Z axis

5 Prime CNC - 20" Z axis

----------------

The 4th axis - 12" Z axis is recommended for 4th axis operation. The Pilot Pro with 12" Z

option or the 5 Prime is requiered.

The BC drive (2 DOF) - The 4th and 5th axis mounted on the Z axis. 5 Prime CNC with 20"

Z axis travel is recommended.

----------------

Setting up the BC drive is easy to do - Here is a video on how to do it

Short Articles

The Basics of CNCs

ebay_feedback

The Basics of CNCs

ebay_feedback